A subsidiary of the Bouygues Group, COLAS specializes in construction operations and materials production. The latter focuses on the manufacture, sale and recycling of road-building materials.

This is achieved by extracting sediment from its quarries and gravel pits, using dredgers mounted on barges. Dredging is carried out using the sling, which consists of an endless chain fitted with buckets. This arm of the bucket dredger lifts the dredged material above the water surface and unloads it onto a nearby conveyor.

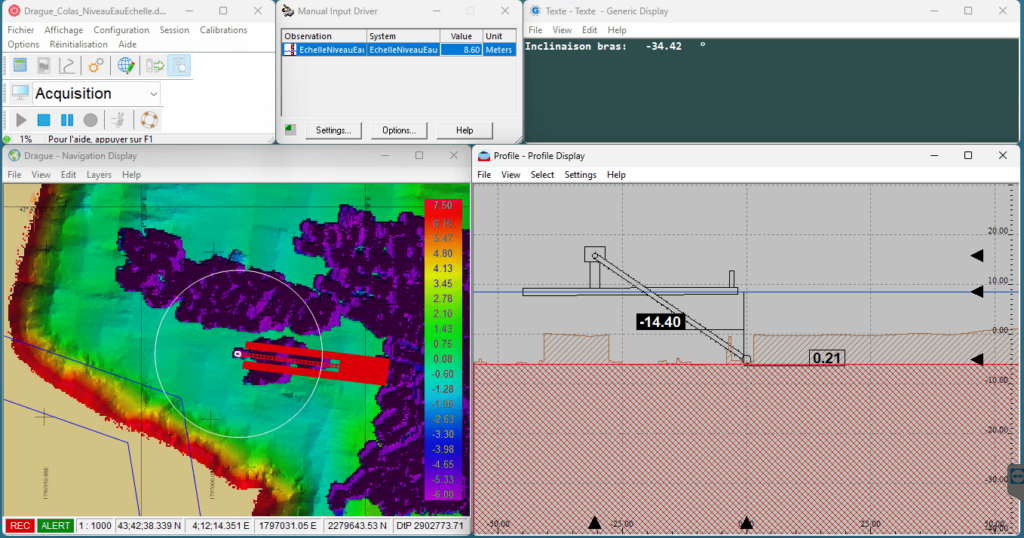

For COLAS, the objective is to know the depth dug into the lake to make a quarry, while respecting a depth limit imposed by prefectoral decree. This constraint requires a technological solution capable of accurately measuring the depth reached during the extraction process.

For this application, CADDEN provided a complete technical solution consisting of the following components:

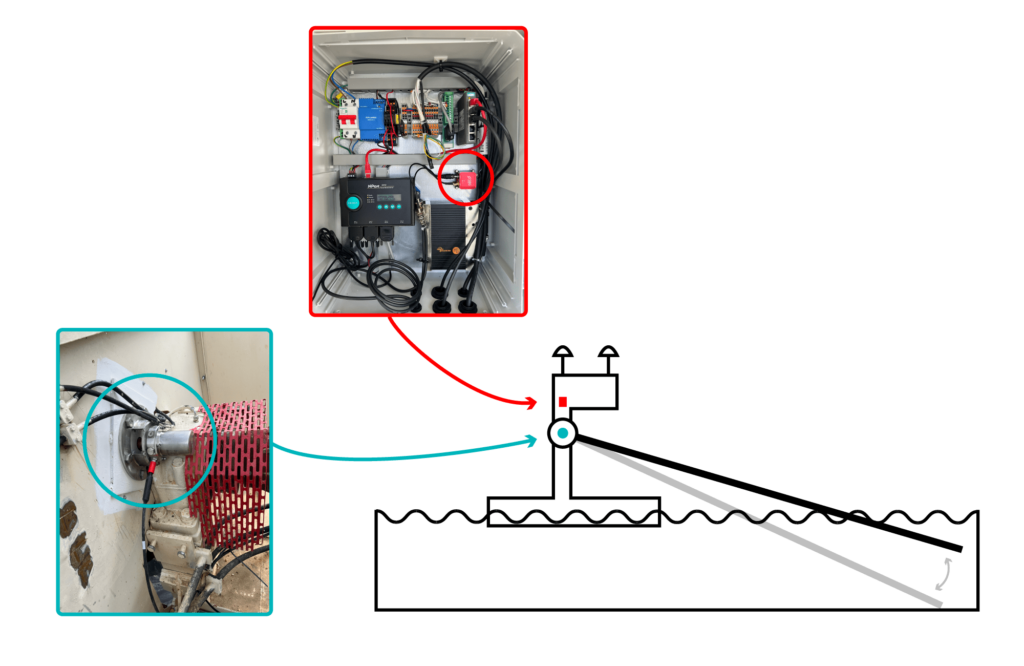

The angle-measuring system is installed directly at the rotation point of the bucket barge arm. Indirect measurements obtained from the inertial unit and the angle sensor accurately calculate the depth reached by the buckets, thus guaranteeing compliance with regulatory constraints.

« Precision and ergonomics were decisive in our selection. The angle sensor and inertial unit met both these criteria », explains Aymeric Dutertre, Materials Equipment Manager at COLAS.

« For us, this system is vital for the machine. We only work with this to make sure we get through everything, especially as the machine works in shifts, so 2 operators are required », adds Mr Dutertre.

In addition to supplying the equipment, our team of Technical Support Engineers was involved in the integration and installation of the equipment, followed by training.

« Everything went very smoothly », enthuses Mr Dutertre.

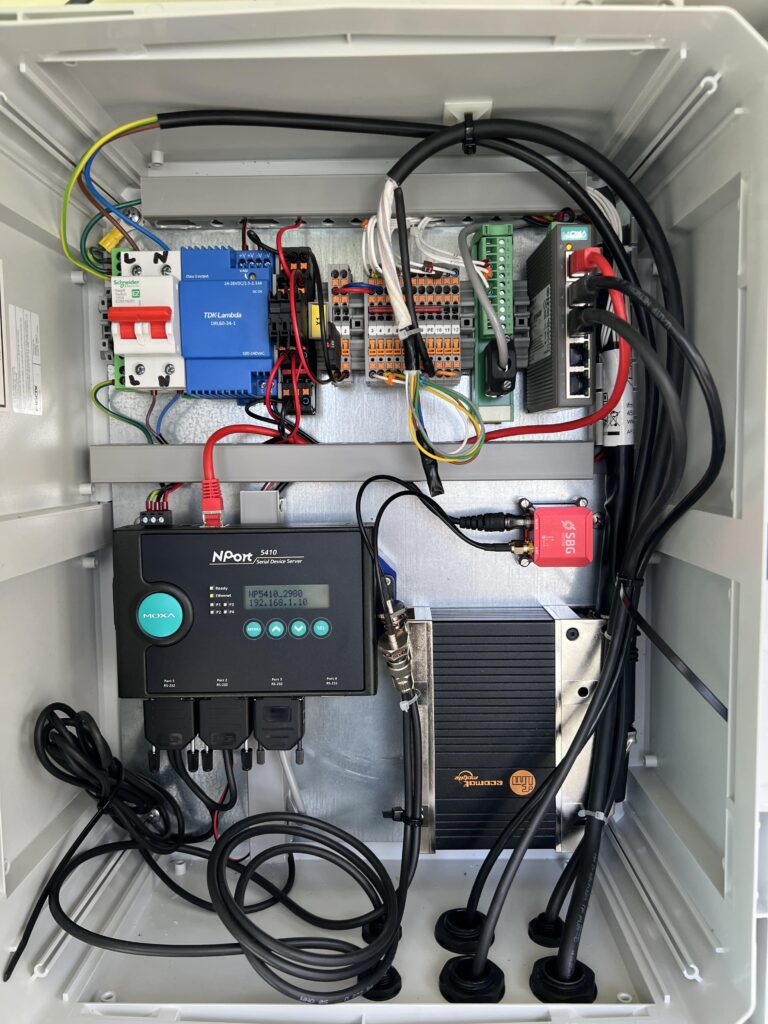

Installation of the equipment involved the integration of a box containing the Ellipse-D Marine inertial unit and the cables required for its operation. This box was connected to the measurement system installed on the barge arm, ensuring precise synchronization with the motions of the windlass.

At the same time, a training session on the use of the Qinsy software was given by our experts to the COLAS teams. This training is dedicated to helping operators understand the solution’s functionalities, equipment configuration, and interpretation of the data obtained.

« We came to know CADDEN through another company, CMSE (Carrière et Matériaux Sud-Est), which owns a barge already equipped with sensors supplied by CADDEN », testifies Mr Dutertre.

Thanks to CADDEN’s expertise and a tailor-made solution, COLAS benefits from a high-performance system to reconcile productivity and regulatory compliance in demanding industrial applications.

Did you like this article ?

Share it with your colleagues or friends