CADDEN to exhibit at 2024 Seanergy in Nantes

Meet CADDEN team at Seanergy 2024 in Nantes

The safety standards of factories and warehouses are an essential point in the life of a company. To continue production activities calmly, it is necessary to guarantee a safe working environment for the employees.

What if you had the ability to quickly stop a running dangerous machine as an operator approaches? When a conveyor breaks and causes errors or someone inadvertently jams their work clothes?

These human errors can sometimes lead to tragic ends. Anticipating these eventualities and choosing an efficient system dedicated to protecting the lives of employees is the best solution to remedy accidents.

Accur8vision’s volumetric sensing system ensures employee safety as important as that of the environment.

The daily use of industrial machines sometimes causes problematic situations, especially if they are not handled correctly.

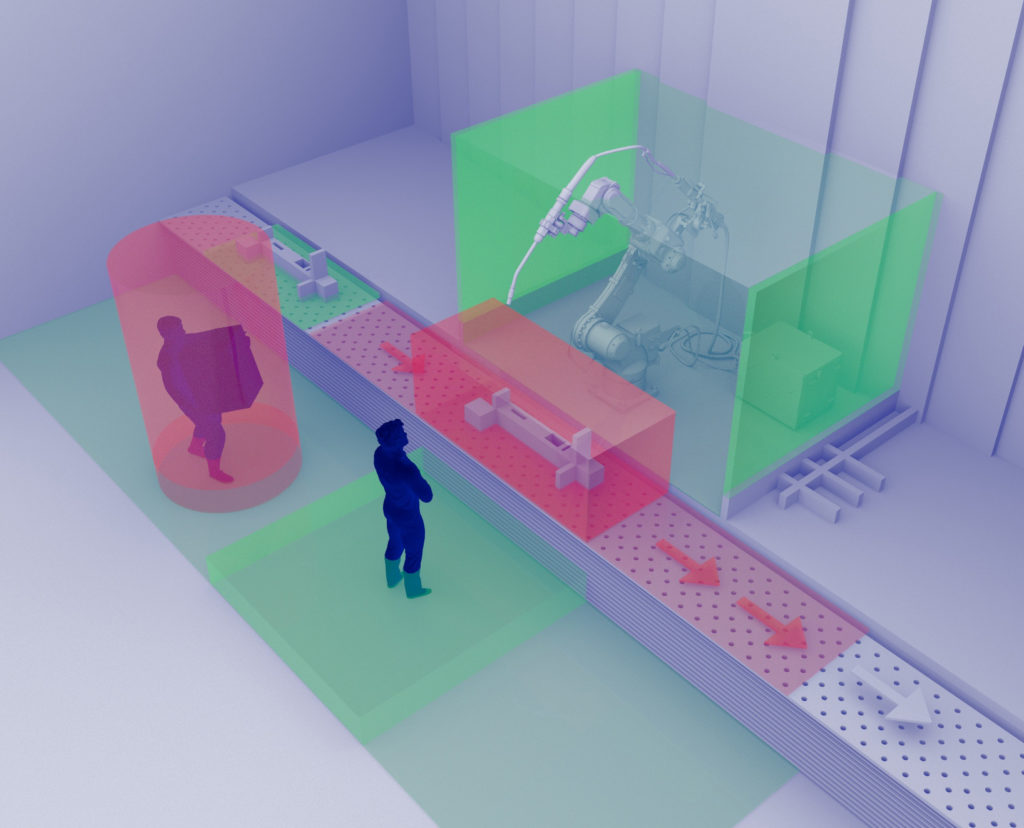

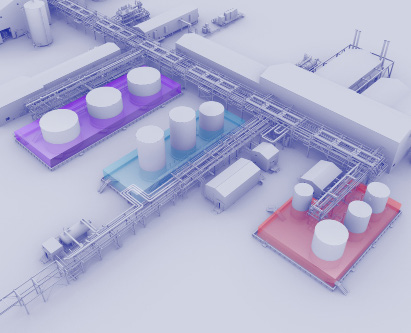

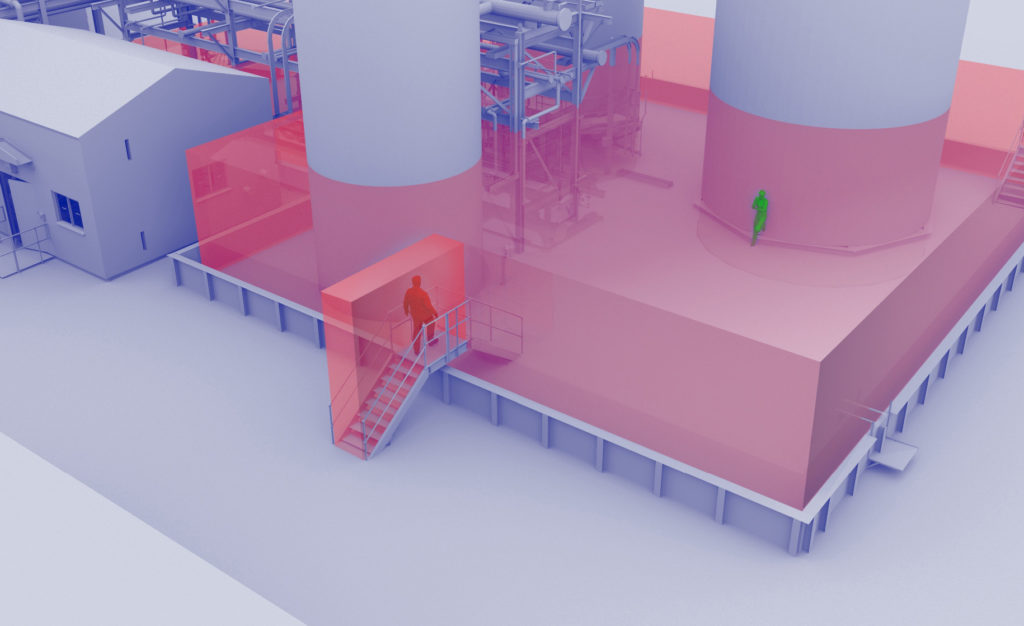

With the Accur8vision volumetric detection system, factories and warehouses are fitted out to delimit secure spaces for personnel around risk areas. Using color codes (eg green for secure spaces and red for high-risk spaces), the locations are easily demarcated.

If an operator wishes to operate the machine while in a hazardous area, it will not turn on until it is located in the secure area. This also applies to assembly line work where many accidents happen with conveyor belts around production lines.

If a so-called risk zone is parasitized, whatever action is taken, an alarm is triggered, shutting down the machines in that zone for safety. The multiple customization features are a real asset in the selection of dedicated areas per machine, without a limited number.

Volumetric detection ensures that employees always stay at a safe distance from machines and thus reduces the risk of workplace accidents.

The volumetric detection system facilitates the recognition of movements thanks to trajectory measurements (employee journeys, movement of goods, etc.). This information is stored in an SQL database, accessible to other systems.

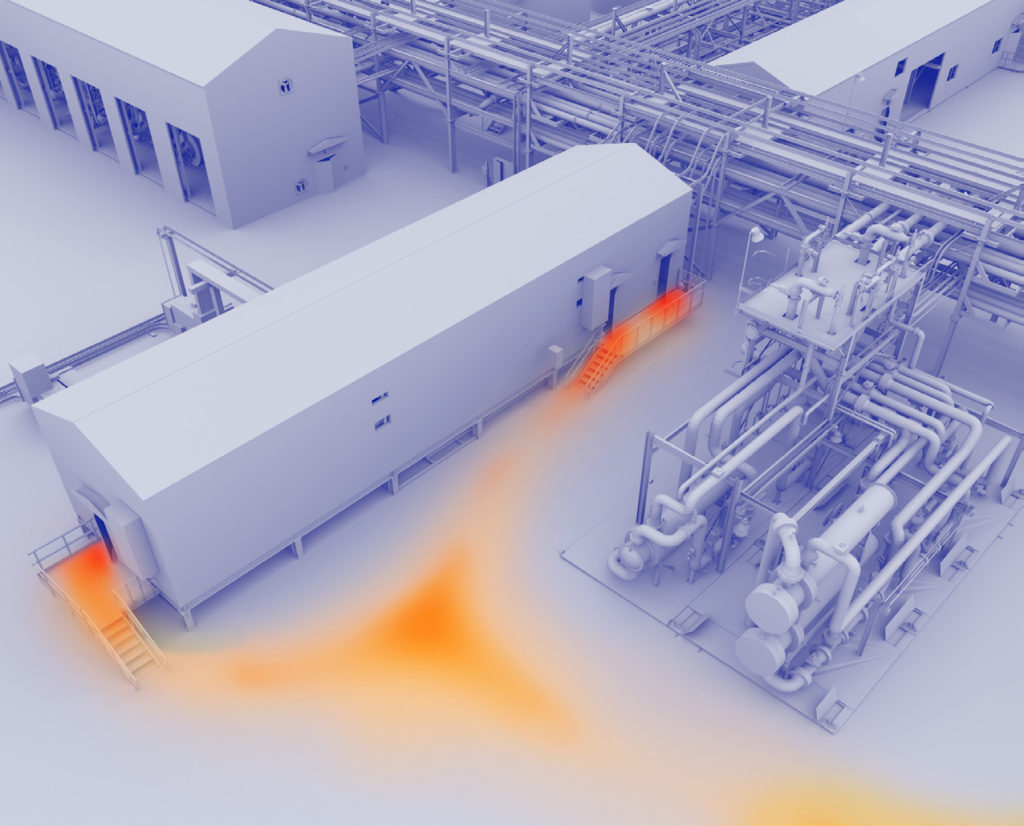

Associated with the Lidar 3D, this solution provides a heat map of data based on moving points transmitted by the Lidar 3D in order to know all the movements in real time.

In this way, companies assess the good points and those that need improvement to maintain security.

In factories, the corridors must be cleared of all clutter to facilitate passage. When this is not the case, it constitutes a safety hazard in the event of fire or accident.

The placement of zones in the corridors can be configured directly on Accur8vision to prevent any risk of clutter and objects left in inconvenient places.

A first scan is performed with the help of a 3D lidar sensor to memorize the area with precision. If the zone is enabled in the system, any new items added to this location after the scan will trigger an alarm if left there too long. The operator will then be warned of the immobilization of the area and to have it evacuated.

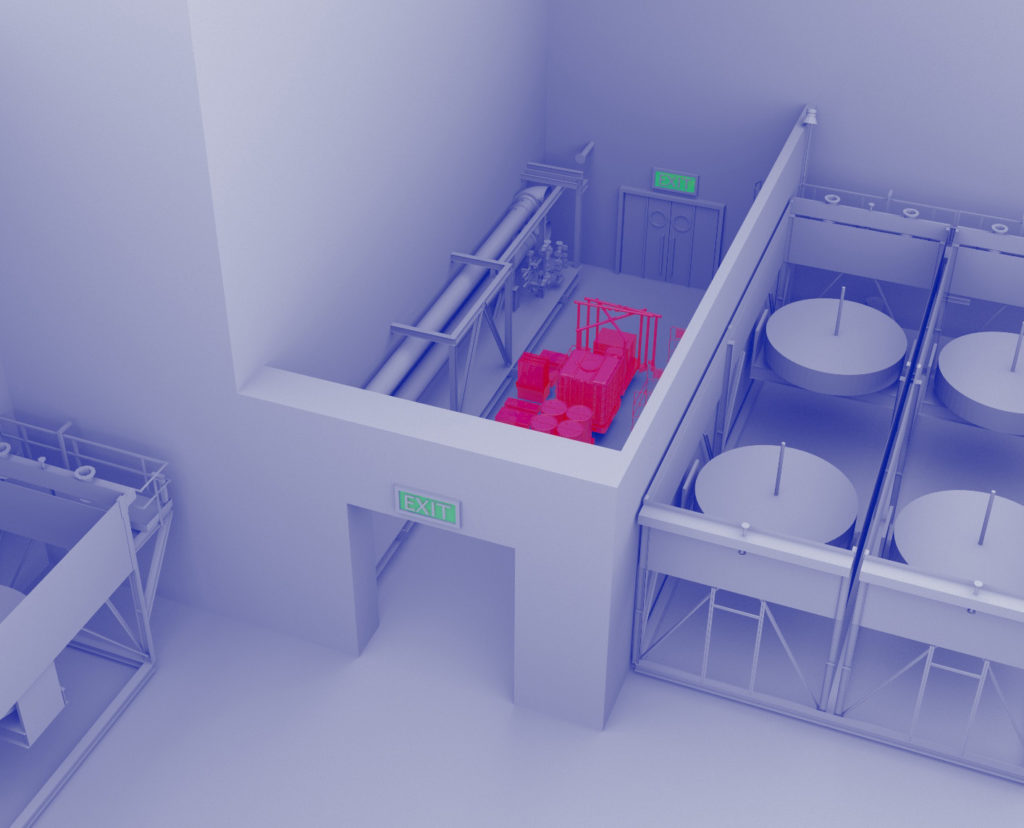

Certain areas of a factory are restricted to certified personnel. The system provides the opportunity to distinguish between authorized and unauthorized personnel.

Hold zones are designed to activate the alarm after a predefined time. If a person enters this area using their badge or access card before the allotted time, the alarm will not go off. This person is authorized to be inside this area.

However, if a person enters this area without presenting a badge or access card in time, the alarm is triggered. This person is not allowed to be in this area. These holding zones are used in different types of scenarios.

This solution also applies when a person arrives in an area for the first time. The employee places his card on the reader and becomes an authorized person; on the system, the surrounding frame changes from red to green, it is free to roam.

An unauthorized person will not know that they are detected and that they are setting off alarms. The security service can follow the unauthorized person without their knowledge, and intervene in a targeted manner in the event of hostile actions.

When it comes to protecting employees and their work environment, Accur8vision is useful in protecting and securing the industry. With the help of zone delineation and a lidar sensor, this solution protects employees and warns them of any danger before an accident occurs.

This system offers complete spatial surveillance of an entire area, and thanks to multiple configuration features, offers many advantages over conventional parametric detection systems.

With the use of Lidar, the system knows the exact position of the object in the real environment and represents the intruder in the 3D map in the exact same position.

The map is an exact replica of the real environment and contains anti-collision measures to navigate within the map. It also serves as a unique coordinate system.

3D zones are zones that activate the alarm and show the path and speed of the intruder. Different types of zones and priorities can be configured.

When you place cameras and Lidars in the 3D map, the planning tools will show you which areas are covered and which areas are not.

The Accur8vision system has the ability to perform a virtual visit of the card with a virtual intruder, in order to test the defined security zones.

Accur8vision is a volumetric detection system using 3D lidar technology to protect entire areas of an environment. The system is programmed to warn of an intrusion into a supervised area. The operator or guard gets precise information about the exact location, size, speed and even the path of the intruder.

Detection is performed using 3D Lidar technology using multi-channel detectors (16 to 128 beams) installed at strategic locations in an environment. The laser beams extend into the chosen area (the range of some detectors is up to 300 m). TOF (Time Of Flight) laser measurements allow precise distance measurement in real time, and the use of multiple lasers supplements these measurements by calculating the volume of the anomaly. A detector performs several hundred thousand measurements per second with an accuracy of 2 to 3 cm.

Meet CADDEN team at Seanergy 2024 in Nantes

Four years ago, Yannick Bestaven and his boat Maître CoQ took the start of the Vendée Globe.

Attend workshops and conferences to discover the latest technological innovations.

Tous droits réservés – 2024

Vos données sont collectées et traitées pour vous envoyer notre newsletter et améliorer l’expérience utilisateur du site web. Dans ce cadre, le responsable du traitement est CADDEN. Vous disposez d’un droit d’accès, de rectification, et de suppression de vos données, ainsi que d’un droit de limitation, de portabilité ou d’opposition. Pour exercer ces droits, vous pouvez nous contacter via le formulaire de contact. Pour plus d’informations sur la façon dont nous traitons vos données personnelles, vous pouvez consulter notre Politique de confidentialité.